Leapfrog Spec Geo Recomendation

The LG.com website utilizes responsive design to provide convenient experience that conforms to your devices screen size. Products.Software.Business Resources About LG Information Display.Business Resources About LG Monitor.Chiller Application Industries About LG EMS Why LG Solar.Media Support Residential.Industries Business Resources About LG ESS About LG Commercial Laundry Industries Business Resources About LG Styler Business Resources About LG Lighting xEV Solution.Infotainment Devices.Safety & Convenience Devices.About LG Vehicle Components Business Resources About LG Compressor & Motor Reference Site Business Resources About LG Membrane.

SPEC flywheels are NOT a one-fits-all lightweight flywheel, though they can be used for an array of driving habits and racing/high performance applications. Consult a SPEC representative for a recommendation. Manufactured from only the highest quality steel and aluminum, they are the only flywheels on the market manufactured to a.001 machine.

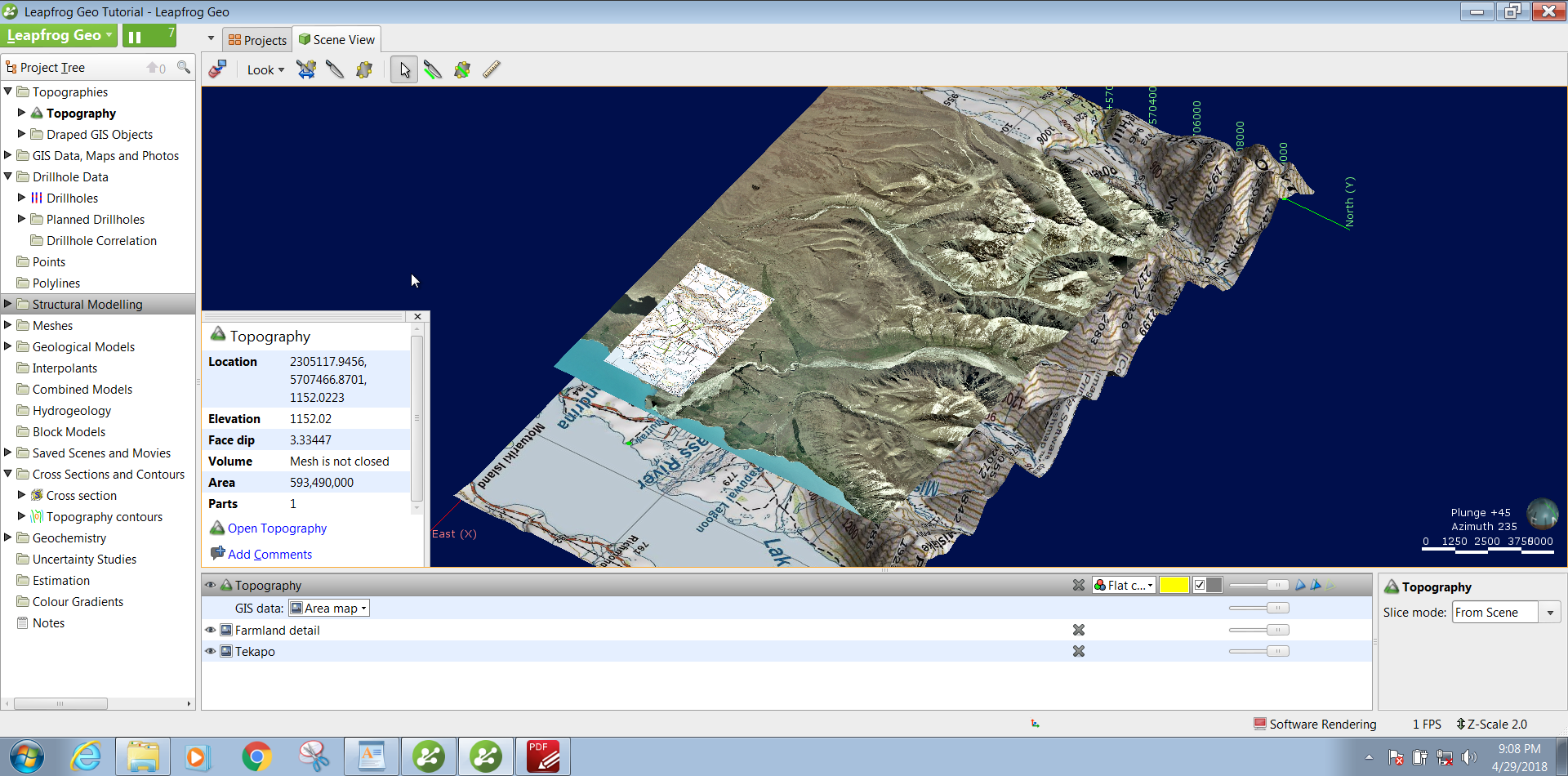

ByLeapfrog has a new surface modelling tool available in the Geological modelling toolset! The offset surface tool will be available to users who have the latest version of Leapfrog Geo or Geothermal.

TheQuiz – Privacy PolicyWe respect your privacy and we are committed to safeguarding your privacy while online at oursite. Emperor Palpatine once told Anakin Skywalker that Darth Plagueis was killed by his apprentice. Darth Plagueis's appearance resembles Snoke. Free online lightsaber test. Question 24 Choose Your Master. Pick a Star Wars quote!

It’s designed to enable a greater degree of flexibility when modelling complex stratified geology, particularly from heterogeneous data. The offset surface tool appropriates all the current dynamic functionality available in the existing geological modelling surface options.So how can the new tool be used to model such deposits? Users of Geo 2.2.1 and earlier may already be familiar with the existing offset tool that was located in the meshes folder. The new tool incorporates much of the same functionality but supersedes the earlier version with improved algorithms and additional editing options.

The new functionality is well suited for modelling faulted, stratified deposits. Folded and faulted offset surface stratigraphy.Stratified deposits by nature have a predictable chronological sequence of lithologies. However the sequences can converge, pinch out, thin and thicken markedly over their expanse. Banded iron ore deposits are representative of such deposits, they were mostly formed between 2400 and 1900 million years ago and represent a large portion of Earth’s economically recoverable iron ore. They were deposited in early proterozoic oceans when oxygen released by photosynthetic cyanobacteria combined with dissolved iron to form insoluble iron oxides, which precipitated out, forming distinctive banded deposits.Following deposition the deposits were often deformed by regional metamorphism and local alteration. In some cases the deformation occurred over multiple tectonic regimes. Minnesota’s Biwabik Iron formation is a good example of such a deposit.

Formed during the middle precambrian period, the Biwabik formation subsequently underwent subduction related rifting, folding and thrusting and then a period of tectonic extension as the midcontinent rift system developed. Banded iron formation Stratigraphy. Deposits are typically explored with a combination of drilling, geophysics and field mapping. The data is not necessarily evenly distributed across the deposit and may consist of information in a range of forms. In this instance quantitative data and geological knowledge may be used to extend the interpretation of the deposit by extrapolating the sequence’s observed true thickness between and away from the data. This can be accomplished with the offset surface tool, either as a constant offset from a reference mesh or an offset between a range of distances.The tool is accessible within the ‘Deposit’ or ‘Erosion’ tools which are located in the ’Geological Models’ ‘Surface Chronology’.

To generate an offset surface first you must create a reference mesh. The offset surface will use the reference mesh to extrapolate the surface away from the known offset data, so it’s important that it’s of high quality. Ideally it will continue to the model or fault block boundary and share a resolution that is comparable to the resultant offset surface.Offset surfaces can be created as either a ‘Constant offset’ surface or from ‘Surface points’. Surface point offset surfaces can incorporate any GIS, polylines and point data available in the project. Constant offset surfaces do not, but instead allow you to select an offset distance and direction you wish the reference mesh to be projected to. Reference mesh and unidirectional surface offset to variably spaced drillholes.Once created offset surfaces built from ‘Surface points’ can be edited to include unidirectional or bidirectional, minimum and maximum distances. Unidirectional offset limits ensure only data on one side of the reference mesh is included whereas bidirectional offset limits ensure data on both sides is honored.

Leapfrog Geo Help

Constant offset surfaces may also be changed in the surfacing editor to be unidirectional or bidirectional surfaces, provided ‘Surface points’ are added. Faulted stratigraphy with pinched out units.